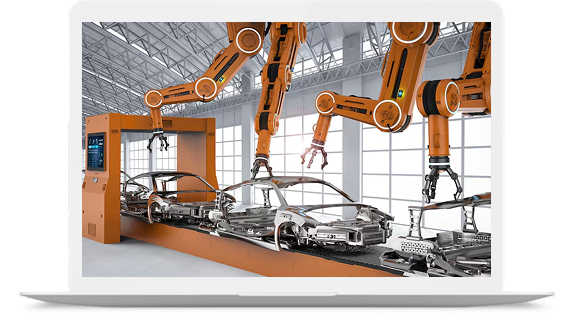

Smart Inventory Management for Automobile Manufacturing

Challenges

- Excess Carrying Costs – Idle inventory consumes capital and floor space unnecessarily.

- Stockouts and Production Delays – Lack of essential parts causes assembly line stoppages, impacting timely delivery.

- Manual Handling Errors – Relying on barcode scanning and manual counts introduces time inefficiencies and mistakes.

- Supply Chain Variability – Fluctuating supplier lead times and unpredictable demand spikes complicate inventory planning and forecasting.

Solution

- IIoT Sensors & RFID Tagging – Automated, continuous stock tracking using RFID tags on pallets and containers eliminates the need for manual scanning and improves accuracy. Geolocation beacons monitor material movement within the factory in real-time.

- AI-Driven Demand Forecasting – Machine learning models analyze historical production data to forecast short-term part requirements accurately. Hybrid forecasting methods further enhance long-term demand predictions to fine-tune reorder points dynamically.

- Automated Material Handling – Autonomous mobile robots (AMRs) transport components on demand from warehouses to assembly lines, while automated storage and retrieval systems (ASRS) optimize storage space and feeding sequences.

- Manufacturing Execution Systems (MES) & Digital Twins – MES synchronizes inventory with production schedules and ERP systems. Digital twins simulate different scenarios, optimizing buffer sizes and workflow layouts, resulting in significant machine utilization and space savings.

Benefits

- Reduced Inventory Carrying Costs – Smart systems help minimize excess stock, freeing up capital and warehouse space.

- Fewer Stock outs & Line Stoppages – Enhanced visibility and automated replenishment reduce unexpected production delays.

- Improved Space Utilization – Automation and optimized storage solutions lead to a more efficient use of warehouse space.

- Enhanced Forecast Accuracy – Advanced AI forecasting models improve the precision of demand predictions, helping to align inventory with production needs.

- Labor Efficiency – Automating inventory tasks with RFID and robotics decreases the need for manual handling, saving time and reducing errors.

Implementation

smart inventory management begins with a thorough assessment of current inventory workflows to identify pain points and inefficiencies. This initial phase includes conducting a pilot project where RFID sensors and gating systems are deployed in a selected production cell to monitor and automate stock tracking. Following this, integration of ERP and MES data takes place, allowing for the development and validation of machine learning models that accurately forecast demand for critical parts, enhancing planning and responsiveness.

Next, automation technologies such as autonomous mobile robots (AMRs) and automated storage and retrieval systems (ASRS) are deployed to streamline material transport and storage operations. Manufacturing Execution Systems (MES) are configured to support autonomous material requests, ensuring smooth inventory flow. Concurrently, a digital twin of the plant is created to simulate inventory buffering and optimize robot routes before expanding the solution. Finally, the system is scaled plant-wide, with continuous monitoring of key performance indicators to drive ongoing improvements and ensure the smart inventory system adapts to changing production needs.